This technology is regarded as one of the most important and common developments in the cutting and machining field.

High-speed cutting technology is an advanced manufacturing technology that exhibits the advantage of improving cutting speed and feed speed. The level of cutting technology determines the quality of industrial products and significantly affects production efficiency and processing costs. The machinery manufacturing industry is the foundation of the national economy and an important index of the comprehensive national strength of a country. Finally, this paper summarizes the positive significance of noise research in high-speed machining and identifies key problems and possible research methods that require further study in the future. The practical application value of condition monitoring based on acoustic signals in high-speed machining is highlighted. In addition, the application of acoustic signals to condition monitoring is also thoroughly analyzed. It provides an effective way for noise control in the process of high-speed cutting. Third, in terms of noise control, a detailed overview is provided from the aspects of the treatment of the noise source that contributes the most to the overall noise, the improvement of the tool structure, the optimization of cutting parameters, and the analysis of contact factors between the tool and the workpiece. The advantages and applicable fields of artificial intelligence algorithms in processing mixed noise source signals with different frequency characteristics are compared, providing ideas for studying the mechanism of noise generation and the identification of noise sources. It is pointed out that accurately analyzing the characteristics of different noise source signals and adopting appropriate methods for identification and processing are the necessary conditions for effectively controlling and reducing the noise in the process of high-speed cutting. Second, in the aspect of noise signal processing, the characteristics of noise signals are analyzed. Then, it points out that a computer achieves high accuracy and practicability in signal analysis, processing, and result display.

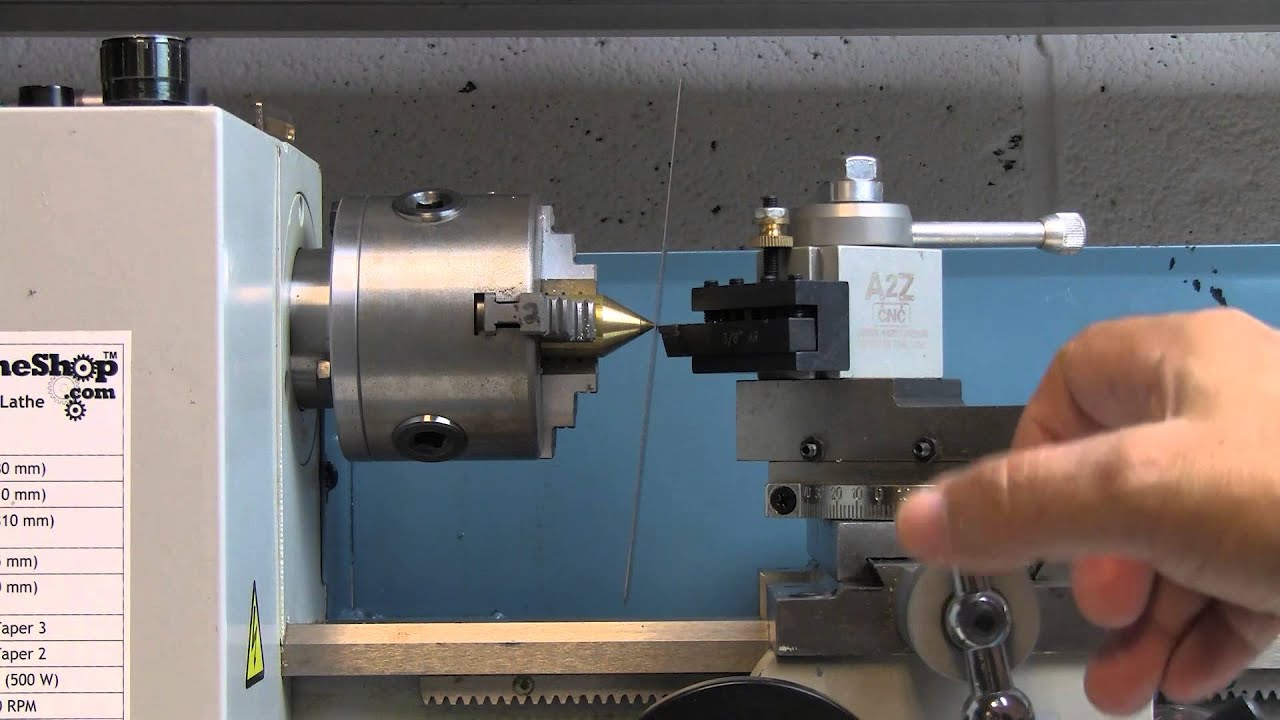

THE CUTTING TOOL ON THE LATHE EXERTS A FORCE HOW TO

It is pointed out that how to accurately classify and recognize the target signal in the complex high-speed machining environment is one of the focuses of scholars’ research.

First, this article introduces noise sources, noise signal acquisition equipment, and analysis software.

To conduct an in-depth study of noise in high-speed cutting machining, this work reviews noise sources, noise collection and numerical recognition, noise control, and condition monitoring based on acoustic signals. However, high-intensity noise generated during high-speed cutting exerts a potential effect on the processing efficiency, processing accuracy, and product quality of the workpiece it may even cause hidden safety hazards. High-speed cutting technology has become a development trend in the material processing industry.

0 kommentar(er)

0 kommentar(er)